Honing is a main process of hole finishing and super finishing. Since the oil stone can be in contact with the workpiece in a larger area during honing, the relative speed and pressure between the abrasive and the workpiece are lower than those in the grinding, and the cutting surface temperature also decreases. Therefore, honing can achieve higher precision stability than mass grinding in surface production, surface roughness and stress-free internal hole surface, which is a good way to efficiently process precision inner holes, elongated holes and blind holes. With the development of high-performance abrasives and high-efficiency automatic honing machines, the application area of ??honing will also be expanded.

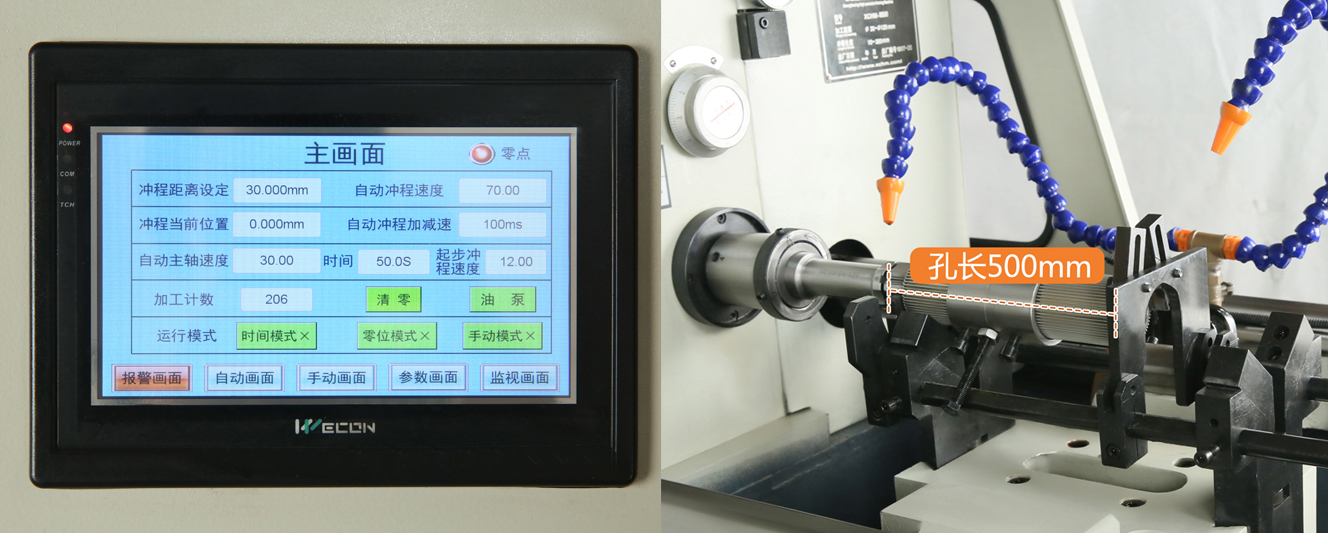

Main technical specifications Processing range:

Hole diameter: Φ25—Φ130mm

Spindle motor: 3KW 0-50Hz inverter motor

Spindle speed: 250-3000 rev/min Stepless speed regulation

Stroke motor: 1.5 KW servo motor

Stroke speed: 20-100 beats / min

Stroke length: 0-350mm

Feed motor: 0.45KW servo motor

Shutdown brake for spindle and stroke: program control

Oil pump motor: 0.125KW

Fuel tank capacity: 120 L

Dimensions: 1900 × 950 × 1350 (length X width X height)

Machine net weight: 900KG

Power source: 380V 50Hz, three-phase four-wire